LUXOR EM A

Both the LUXOR E A and LUXOR EM A dryers with optional ETA plus® energy saving technology are specifically designed to supply consistently low dew-point air to one drying bin, while reducing energy consumption.

The LUXOR E A dryer is designed for use with existing conveying systems or hopper loaders.

Whereas the LUXOR EM A offers a machine dedicated solution with integrated dry air conveying for up to two processing machines and the drying bin.

There are three sizes with drying bin capacities of 60, 100 and 150 litres.

The LUXORnet controls utilise modern, flexible BUS-technology. As standard, the colour touch control manages the dry air generator, one drying bin and with the EM version, material conveying to one drying bin and two processing machines. The integration of dry-air conveying and material proportioning provides maximum flexibility and productivity.

- ×

Dry air dryer

LUXOR EM A

ETA plus® technology

Innovative and energy efficient drying technology which saves you money.Optional ETA plus® technology stands for innovative and energy-efficient drying technology which takes two individual factors into consideration:

- The process air flow control adapts automatically the mass flow of air to the amount of material being dried as well as to seasonal and time-of-day related fluctuations.

- Once the mass air flow has been reduced to its minimum value, the drying temperature adapts automatically to the amount of material being dried. This guarantees very gentle drying, especially when there is a large drop in material throughput rates.

Altogether, the combination of air flow control and temperature reduction offers the highest possible energy savings.

Compared with conventional drying systems, energy savings of up to 64% are possible with ETA plus® technology.

Both functions can be either enabled or disable dependant on your process requirements.

Dry air dryer

LUXOR EM A

Dew-point indication and control.

Optimised regeneration time saves energy.Optional dew-point indication and control. Regeneration of the molecular sieve is triggered when the maximum dew-point set value of the return air has been reached. This value can be defined and set by the user and offers large energy savings.

Dry air dryer

LUXOR EM A

The four drying parameters

Optimum drying results in the correct combination of all four drying parameters.An energy-efficient drying is only achieved by optimally manging the four drying parameters: dry air flow, drying time, drying temperature and dew-point.

Dry air dryer

LUXOR EM A

Molecular sieve

Reliable with a long service life.Each time molecular sieve is regenerated it needs to be heated up and then cooled down. This causes friction and generates dust which blocks the moisture trapping pores in the molecular sieve.

motan uses specially designed and prepared molecular sieve with a high mechanical and chemical stability. This reduces the frequency that the sieve needs to be exchanged and ensures optimum dry air quality.

Dry air dryer

LUXOR EM A

LUXORBIN geometry

Drying bin geometry - essential for correctly dried material.The ratio between the height and diameter of a drying bin is critical to how a material flows through the bin. Incorrect mass flow can lead to "dead" corners where the material is over dried or the material will flow too quickly through the middle of the bin resulting in under dried material.

The optimum dimensions of motan LUXORBINs are determined by calculation and practical tests, guaranteeing correctly dried material is delivered to your processing machine.

Dry air dryer

LUXOR EM A

Large clean out door

Easy access and quick clean down.The larger 100 and 150 litre drying bins are equipped with especially large clean out doors fitted with a sight glass and easy-to-open quick release handles.

They fit the shape of the bin in order to optimise material flow and simplify cleaning. In addition, they have a split hinged lid for easy access from above.

Dry air dryer

LUXOR EM A

LUXORBIN construction

Designed for reliability and a long life.All motan LUXORBINs are made of stainless steel and are completely insulated including the bin cone. The bins are mounted on solid frames and have a control box mounted at the front of the bin for optimum accessibility.

The long-life solid state relays guarantee precise and reliable temperature control that does not damage thermally-sensitive materials.

Dry air dryer

LUXOR EM A

Material database

Simplified use and less errors.To simplify the input of the material-related drying parameters such as drying time and temperature, a material database is integrated in the control.

The database includes a data pool with parameters for about 70 standard materials and can accommodate up to 80 data sets as specified by the customer.

Dry air dryer

LUXOR EM A

Integrated conveying

Saves space and money.The integrated conveying function in the LUXOR EM A saves you space and money as no separate conveying system is needed.

It can control one material loader on the drying bin and up to two loaders feeding the processing machines, as well as the blower and filter.

For the installation of larger systems, you can connect LUXOR EM A dryers with a central WEBpanel allowing you to control all functions remotely and providing an overview of the entire production. This guarantees a high degree of flexibility.

Dry air dryer

LUXOR EM A

METRO G material loaders

High quality system conveying as standard.METRO G system loaders are used to convey the plastic granulate quickly and cleanly to the processing machine or drying bin.

Material is delivered exactly when needed, keeping machines running and avoiding costly downtime.

Material wastage is eliminated and the work-space is kept clean and safe.

Dry air dryer

LUXOR EM A

Conveying pipework

Making your life simpler.For easy setup, pre-configured material feedline sets are available for one or two machines. The option of stainless steel vacuum and conveying pipework at the back of the drying bin, enables a simple and effective connection to the processing machines.

Dry air dryer

LUXOR EM A

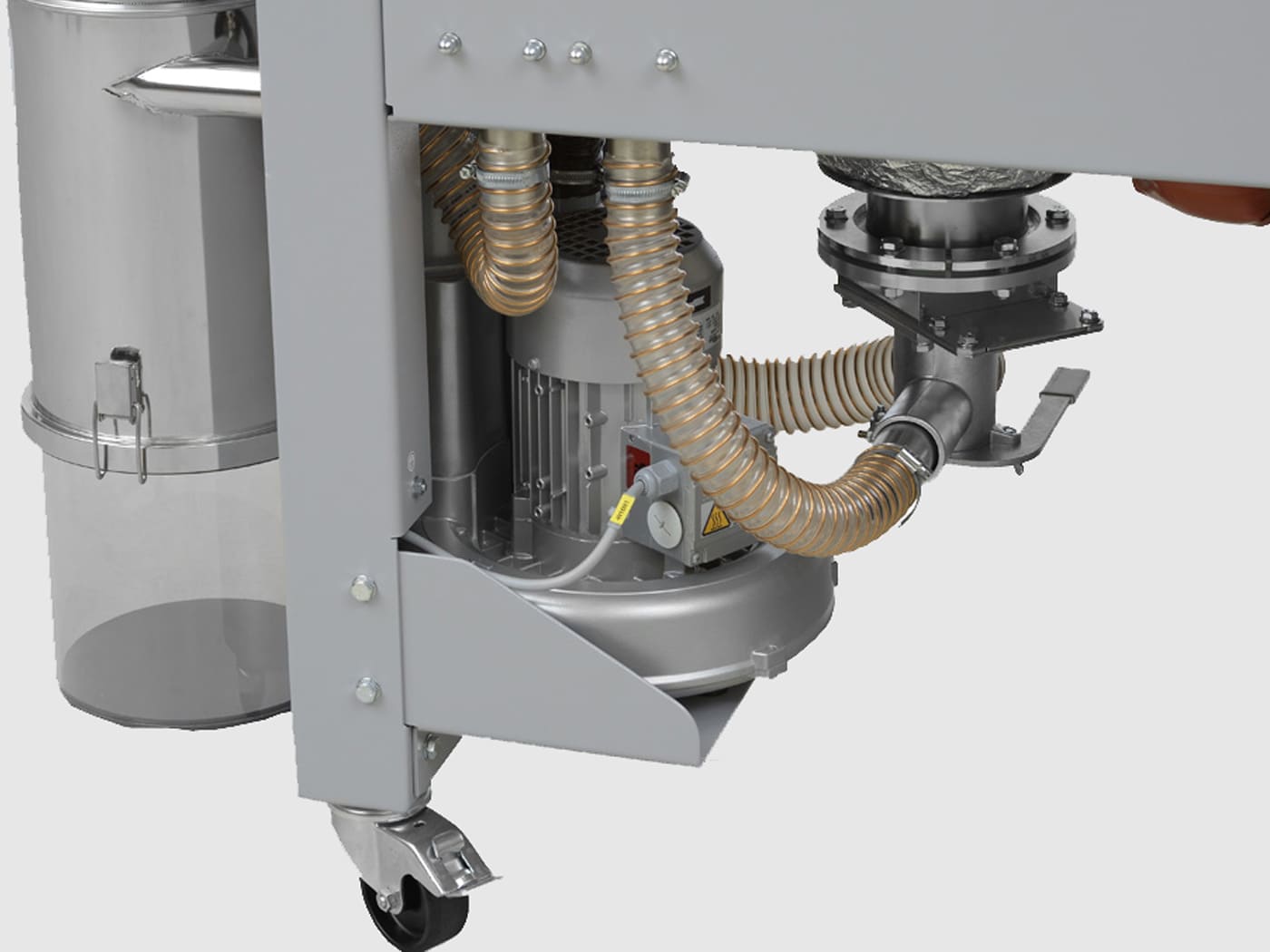

Side-channel blower for conveying

Maintenance free, reliable, and quiet.Perfect for moderate distance conveying applications, nothing beats the simplicity of a side-channel vacuum blower.

motan blowers utilize a one-piece fan and side-channel unit to produce reliable vacuum power. The simple, quiet and compact design allows the pump to be installed under the drying bin.

Dry air dryer

LUXOR EM A

Cyclone and fine dust filter for conveying

High quality dust collection as standard.The cyclone dust filter offers you efficient filtering for small to medium throughput conveying. The cyclone separates the dust and a transparent dust collection bin with quick release clips, makes for an easy removal of fines.

Dry air dryer

LUXOR EM A

Material proportioning valve

Accurate and reliable addition and mixing of regrind and virgin materials.The electro-polished stainless steel METROMIX proportioning valve is attached to a METRO G material loader.

You can easily adjust the percentage and number of material layers per conveying cycle at the dryer control. A large transparent access panel gives you easy access for cleaning.

Dry air dryer

LUXOR EM A

Dry air conveying

Maintaining material temperature and eliminating reabsorption of moisture.Dry air conveying is essential for hygroscopic materials which reabsorb moisture quickly. Conveying is carried out in a closed loop and dry, warm air is used for transporting the material to the processing machine, maintaining material temperature and eliminating reabsorption of moisture.

Dry air dryer

LUXOR EM A

Line purging

Ensuring correctly conditioned material is delivered to the machine.Conveying from the drying bin to the processing machine is done via a no-dead-space suction box made of stainless steel with an integrated purge facility, guaranteeing very low residual moisture content and a constant material temperature.

Automatic line purging is available as an option.

Dry air dryer

LUXOR EM A

LUXORnet E & EM controls

State-of-the-art control with innovative, Ethernet-based open network architectureThe LUXORnet E & EM controls offer user-friendly operation via a colour graphic display with touch screen.

The control incorporates comprehensive functions for operation and process control, recipe management, reporting for quality assurance, as well as enhanced service functions and trend charts. ETA plus® airflow control with temperature adaptation is available as an option.

The LUXORnet control utilises modern, flexible BUS technology. As standard, the control manages the dry air generator, one drying bin, as well as up to three material loaders.

LUXORnet technology stands out due to its modern, Ethernet-based open network architecture enabling you to connect LUXOR EM A dryers with a central WEBpanel this allows you to control all functions remotely and provides an overview of the entire production.